You might have heard that all air compressor oils are the same, but let me tell you, that couldn’t be further from the truth. As an SEO expert with years of experience in ranking blogs on Google, I’ve come across this misconception time and time again. The reality is, choosing the right air compressor oil is crucial for the performance and longevity of your compressor. In this blog post, I’m going to debunk this common myth and provide you with expert tips for selecting the best air compressor oil.

Understanding Air Compressor Oil

Air compressor oil is not just any ordinary lubricant; it plays a vital role in the proper functioning of your compressor. Unlike motor oil, which is designed for engines, compressor oil is formulated specifically to withstand the high pressures and temperatures found in compressors. Its primary functions include lubricating moving parts, sealing gaps to prevent leaks, and dissipating heat to keep the compressor running smoothly.

Types of Air Compressor Oil

When it comes to air compressor oil, one size definitely does not fit all. There are several types of compressor oil available on the market, each with its own unique properties and advantages. Synthetic oils, for example, offer superior performance in extreme temperatures and provide better protection against wear and corrosion. On the other hand, mineral oils are more affordable and suitable for standard operating conditions. Semi-synthetic oils combine the best of both worlds, offering increased durability and performance without breaking the bank. It’s essential to consider factors such as compressor type, operating conditions, and manufacturer recommendations when choosing the right oil for your compressor.

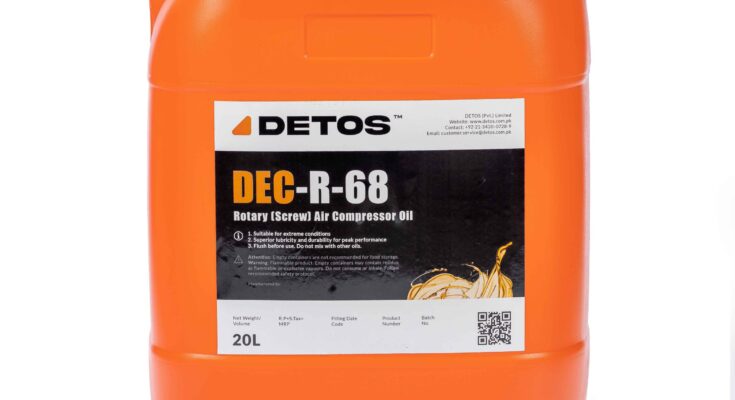

Photo By: jamecpem.com

Factors to Consider When Choosing Air Compressor Oil

Choosing the right air compressor oil involves more than just picking a type off the shelf. Several factors come into play, each of which can impact the performance and longevity of your compressor. Viscosity, for example, is a critical consideration as it affects the oil’s ability to flow and lubricate moving parts effectively. Additionally, oxidation stability is crucial for preventing the oil from breaking down under high temperatures and prolonged use. Additive packages can also enhance the oil’s performance by providing additional protection against corrosion, foaming, and wear. By evaluating these factors carefully, you can ensure that you select the best air compressor oil for your specific needs.

Synthetic Compressor Oil: A Closer Look

Synthetic compressor oil stands out for its exceptional performance in demanding environments. Engineered to withstand extreme temperatures and heavy loads, synthetic oils offer superior lubrication and protection compared to their mineral counterparts. With excellent oxidation resistance and extended service intervals, synthetic compressor oils ensure consistent performance and prolonged compressor life. However, the higher cost may deter some users, making it essential to weigh the benefits against the investment.

Mineral Compressor Oil: Exploring Cost-Effective Lubrication

Mineral compressor oil provides a budget-friendly option for those operating under standard conditions. While lacking the advanced features of synthetic oils, mineral oils offer reliable lubrication and protection for most compressors. With good thermal stability and compatibility with a wide range of equipment, mineral compressor oils are a popular choice among users seeking cost-effective solutions. However, their performance may falter under extreme temperatures or heavy loads, necessitating more frequent oil changes and maintenance.

Semi-Synthetic Compressor Oil: Finding the Middle Ground

Semi-synthetic compressor oil combines the best attributes of synthetic and mineral oils, offering enhanced performance without the premium price tag. With improved oxidation resistance and thermal stability, semi-synthetic oils provide reliable lubrication in a variety of operating conditions. While they may not match the performance of full synthetic oils, semi-synthetic lubricants offer a cost-effective compromise for users seeking improved durability without breaking the bank.

Photo By: hi-tecoils.com.au

Verdict: Choosing the Right Air Compressor Oil for Your Needs

In conclusion, selecting the right air compressor oil requires careful consideration of various factors, including compressor type, operating conditions, and performance requirements. Synthetic oils offer unmatched protection and longevity but come at a higher cost. Mineral oils provide a budget-friendly alternative for standard applications but may require more frequent maintenance. Semi-synthetic oils strike a balance between performance and affordability, making them a popular choice for many users. By understanding the unique features and pros and cons of each type of air compressor oil, you can make an informed decision that maximizes the performance and longevity of your compressor.

FAQs

- What is the difference between air compressor oil and regular motor oil? Air compressor oil is specially formulated to withstand the high pressures and temperatures found in compressors, whereas regular motor oil is designed for engines. Compressor oil has unique additives and properties tailored to lubricate moving parts, seal gaps, and dissipate heat efficiently.

- How often should I change my air compressor oil? The frequency of oil changes depends on various factors such as the type of compressor, operating conditions, and oil quality. As a general rule of thumb, it’s recommended to change the oil every 3 to 6 months or as specified by the manufacturer.

- Can I mix different types of compressor oil? Mixing different types of compressor oil can affect performance and may void warranties. It’s best to stick to the recommended oil type specified by the manufacturer to ensure compatibility and optimal performance.

- What are the signs that my compressor oil needs to be changed? Common signs that indicate it’s time to change the compressor oil include decreased performance, increased noise levels, excessive heat, and visible contaminants in the oil. Regular oil analysis can also help monitor oil condition and identify potential issues early on.

- Is synthetic compressor oil worth the extra cost? Synthetic compressor oil offers superior performance and longevity compared to mineral oils, making it worth the investment for users operating in extreme conditions or requiring extended service intervals. However, the decision ultimately depends on your specific application and budget constraints.

- Can I use automotive oil in my air compressor? It’s not recommended to use automotive oil in air compressors as it may not provide adequate lubrication and protection under the high pressures and temperatures experienced in compressor operations. Using the wrong type of oil can lead to premature wear and damage to the compressor.

- How do I dispose of old compressor oil? Proper disposal of old compressor oil is essential to protect the environment. Many auto parts stores and recycling centers accept used oil for recycling. Alternatively, you can contact your local waste management facility for guidance on proper disposal methods in your area.

- Can I reuse compressor oil after filtering it? While filtering used compressor oil can remove some contaminants, it’s generally not recommended to reuse oil due to the risk of residual contaminants and degradation. It’s safer and more cost-effective to use fresh oil for optimal compressor performance.