How Does an Air Compressor Work?

You might think air compressors are complicated machines only experts can understand. But that’s not true! With a little bit of guidance, anyone can grasp the basics of how does an air compressor work. Whether you’re a DIY enthusiast or just curious, this guide will make it simple and clear.

Introduction

Hook: Ever wondered how does an air compressor work can power up so many tools and machines with just a puff of air? It’s like magic, but with a bit of science behind it!

Brief Overview: In this blog, we’re diving into the nitty-gritty of how does an air compressor workworks. We’ll break down the process step by step, explore the key components, and see why understanding this is so important for both beginners and seasoned pros.

Importance: Knowing how does an air compressor work works isn’t just for mechanics. It’s valuable for anyone using power tools, working on DIY projects, or needing to handle maintenance tasks. Plus, it’s pretty cool to understand the science behind these powerful machines!

What is an Air Compressor?

Definition: So, what exactly is an air compressor? At its core, an air compressor is a device that converts power into potential energy stored in compressed air. Think of it as a pump, but for air instead of liquids.

Basic Function: The main function of an air compressor is to take in air at atmospheric pressure and squeeze it into a smaller volume, increasing its pressure. This compressed air can then be used to power various tools and machines, making tough jobs a breeze.

Uses: Air compressors are incredibly versatile. You’ll find them in garages, construction sites, workshops, and even in your local dentist’s office. They’re used for inflating tires, operating pneumatic tools like nail guns and drills, and even in spray painting. Knowing how does an air compressor work for power tools can open up a world of DIY possibilities!

Understanding the Basics

Now that we’ve covered what an air compressor is and why it’s useful, let’s break down the basic components and how they work together.

Compressor Pump: The pump is the heart of the air compressor. It’s where the magic happens. This component is responsible for drawing in air and compressing it. Depending on the type of air compressor, the pump can be a piston, rotary screw, or vane. For example, in a piston air compressor, the pump uses a piston driven by a crankshaft to compress air.

Motor: The motor powers the compressor pump. It can be electric, gas-powered, or even diesel-powered. Understanding how does an air compressor motor work is essential because the motor is what makes the pump operate. Without the motor, the entire system would be dead.

Tank: Once the air is compressed, it needs to be stored somewhere. This is where the tank comes in. The tank holds the compressed air at high pressure until it’s needed. The size of the tank can vary depending on the model and application, but its main job is to ensure a steady supply of compressed air.

Other Parts: Other essential components include pressure gauges to monitor air pressure, hoses to deliver the air to tools, and various valves and regulators to control the flow and pressure of the air.

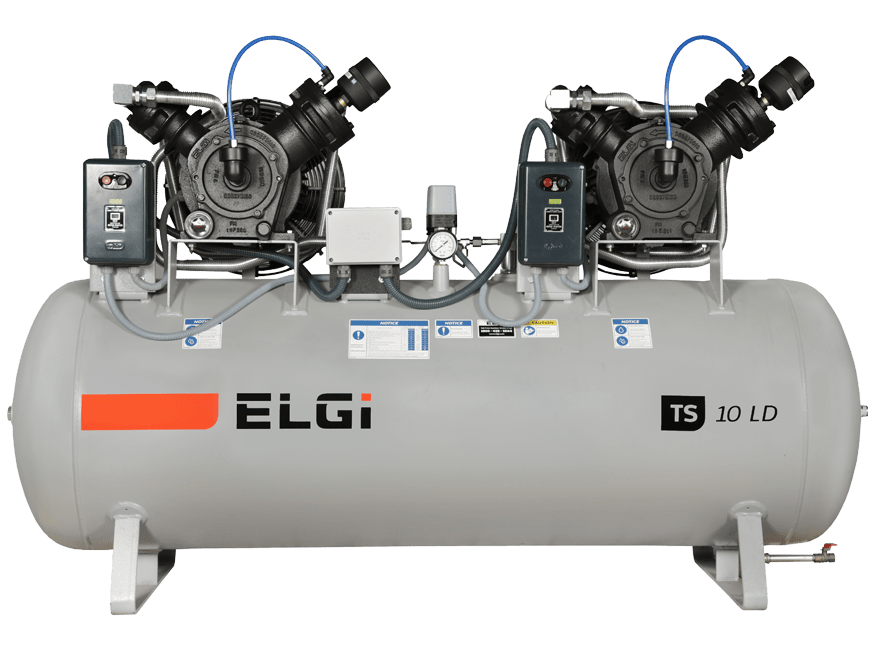

Photo By: elgi.com

How Does An Air Compressor Work?

Let’s get into the nuts and bolts of it. How does an air compressor work?

Step-by-Step Process:

- Air Intake: The process starts with the air intake. The air compressor draws in air from the surrounding environment through an intake valve. This air is at atmospheric pressure.

- Compression: The compressor pump then compresses the air. In a piston compressor, a piston moves down to create a vacuum, drawing in air, and then moves up to compress it into a smaller volume. Rotary screw compressors use two rotating screws to compress the air as it moves through the screws.

- Air Storage: After compression, the air is stored in the tank. The tank holds the air at a high pressure, ready to be used whenever needed.

- Air Release: When you’re ready to use the compressed air, it’s released through a hose and directed to your tool or machine. The pressure regulator ensures the air is delivered at the correct pressure.

Compression Cycle: The cycle of compressing air, storing it, and releasing it can happen continuously. The air compressor will kick in to compress more air whenever the pressure in the tank drops below a certain level. This automatic cycle ensures there’s always a supply of compressed air ready to go.

Air Intake and Compression: Let’s take a closer look at the air intake and compression process. The intake valve opens, allowing air to enter the cylinder. In a piston compressor, the piston moves downward, drawing in the air. Then, the piston moves upward, compressing the air into a smaller space. This compressed air is then pushed into the storage tank.

Air Storage and Release: Once in the tank, the compressed air stays at high pressure until it’s needed. When you use a tool, the valve opens, allowing the air to flow out of the tank, through the hose, and into the tool. The pressure regulator ensures that the air is delivered at the right pressure, whether you’re inflating a tire or using a pneumatic drill.

By understanding these components and processes, you can appreciate the efficiency and functionality of air compressors. They are remarkable machines that make many tasks easier and more efficient.

Pros and Cons of Air Compressors

Air compressors have numerous advantages. They provide a reliable and powerful source of energy for various tools and applications. They can be used in numerous settings, from home garages to industrial factories. Their versatility and power make them indispensable in many fields.

However, there are also some downsides. Air compressors can be noisy, especially the larger industrial models. They require regular maintenance to ensure they operate efficiently and safely. Additionally, initial costs can be high, although this is often offset by their long-term benefits and efficiency.

Photo By: namerah.com

Final Verdict

Understanding how does an air compressor work, from the intake of air to the release of compressed air, highlights its complexity and efficiency. These machines are marvels of engineering, providing essential power in a wide range of applications. Whether for professional use or DIY projects, knowing how your air compressor functions can help you use it more effectively and maintain it properly.

Frequently Asked Questions about Air Compressors

Q1: What exactly is an air compressor?

An air compressor is a machine that converts power into potential energy stored in compressed air. It takes in air at atmospheric pressure, compresses it into a smaller volume, and stores it in a tank until it’s needed.

Q2: How does an air compressor work?

An air compressor works by drawing in air through an intake valve, compressing it using a pump powered by a motor, and then storing the compressed air in a tank. When you need to use the compressed air, it’s released through a hose and regulated to the correct pressure for your tool or application.

Q3: What are the main components of an air compressor?

The main components of an air compressor include the compressor pump, motor, tank, pressure gauges, hoses, and various valves and regulators. Each part plays a crucial role in the operation and efficiency of the compressor.

Q4: What types of motors do air compressors use?

Air compressors can use electric motors, gas-powered motors, or diesel-powered motors. Electric motors are common in residential and light commercial settings, while gas and diesel motors are preferred for heavy-duty and remote operations.

Q5: Why is the tank important in an air compressor?

The tank holds the compressed air at high pressure until it’s needed. It ensures a steady supply of compressed air and allows the compressor to operate more efficiently by reducing the need for continuous running.

Q6: How often do I need to maintain my air compressor?

Regular maintenance is essential for keeping your air compressor in good working condition. This includes checking and changing the oil (if applicable), inspecting and replacing air filters, draining the tank to remove moisture, and checking for any leaks or worn parts.

Q7: Can air compressors be used for multiple applications?

Yes, air compressors are incredibly versatile. They can be used for inflating tires, powering pneumatic tools like nail guns and drills, spray painting, and even in medical and dental settings. The key is to ensure the compressor provides the correct pressure and volume of air for the specific application.

Q8: Are air compressors noisy?

Some air compressors can be quite noisy, especially larger industrial models. However, many modern compressors are designed to be quieter. If noise is a concern, look for models labeled as “quiet” or “low-noise.”

Q9: What are the pros and cons of using an air compressor?

Pros include the versatility, power, and efficiency of air compressors. They’re reliable and can be used in many different settings. Cons include the potential for noise, the need for regular maintenance, and the initial cost of purchasing a quality unit.

Q10: How can I ensure my air compressor lasts a long time?

Regular maintenance is key. Make sure to follow the manufacturer’s guidelines for oil changes, air filter replacements, and tank draining. Keep the compressor clean and inspect it regularly for any signs of wear or damage. Proper usage according to the compressor’s specifications will also help extend its lifespan.