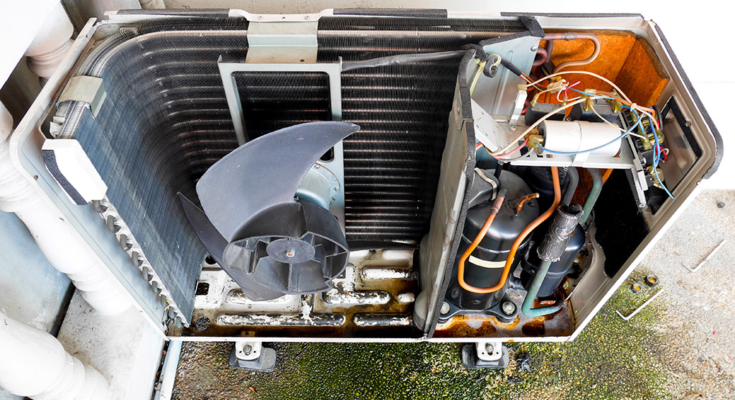

Air compressors are strong, essential tools that make a range of difficult activities simpler. These powerful tools have been used in industrial and commercial settings to such an extent that facilities simply cannot function without them. Now it is usual that you think about What Causes air compressor to fail. Additionally flexible and adaptable, air compressors come in a variety of models designed for various applications. They keep the house tidy and functional.

Air compressors, like other heavily used gear, require routine maintenance to maintain effectiveness and efficiency. But frequent use puts them vulnerable to damage. Issues will ultimately arise. Thankfully, it doesn’t have to be expensive. Air compressors need routine inspection and maintenance to ensure they are working effectively, just like any heavy-duty gear. Here it is important for homeowners to know What causes air compressor to fail?

Several factors might cause air compressors to malfunction: A few examples are standard wear and tear, the unit’s lifespan and age, poor maintenance, power surges, and installation problems. In this write up we will discuss what causes air compressor to fail. So, keep reading!!!

Reasons Why Air Compressors Fail

You should find any issue that could result in the compressor failure of your air conditioner as soon as you can because compressor repair or replacement is an expensive proposition. The following are early warning indicators that your compressor is ready to malfunction or we can say What Causes air compressor to fail:

Airflow Weakness

One of the initial signs of AC compressor failure is decreased airflow. If you believe that your home is not chilly enough, you may continue to lower the temperature over the first few days, making it difficult to notice the change. Placing your hands under the vents is the best way to examine whether the airflow is weak. If you experience little airflow or warm air when cooling, your air conditioner’s compressor may be malfunctioning. Weak airflow leads to What Causes air compressor to fail.

Strong Banging Sounds

You should be informed if your HVAC system begins to make loud noises and you observe tremors. Failure of the compressor is one of the issues indicated. The compressor is having problems starting and is most likely to fail in the future based on these AC noises. The compressor’s electrical parts failing is indicated by the hammering noise. This is also What Causes air compressor to fail.

Refrigerant Leak

Weak air flow, hissing noises, water around your HVAC unit, or the development of ice on the evaporator coils are factors of leak refrigerant. It should be fixed because it may lead to other problems also What Causes air compressor to fail. In long, it may result in compressor failure and affect the cooling of your system.

Circuit Breaker Trip

Circuit breakers trip as a safety precaution to save your gadgets from an electrical breaker. It occurs when there is a power spike or when you have too many gadgets running at once. It is not a good indicator and suggests compressor failure if your unit trips the circuit breaker frequently. It indicates that your compressor is overheated and needs more power to operate. Circuit breaker also one of the main factors of What Causes air compressor to fail.

Overheating

One frequent reason for air compressor failure is overheating. However, when the air in the work area is too hot and humid, overheating is still a problem. The air flow is typically blocked by the machine being placed against a wall or other obstruction, the compressor room vents being blocked, or both. Oil lines that are clogged or unclean, which cause oil to degrade and lose viscosity, are another reason for overheating. The internal components of the air compressor will begin to grind against each other if the overheating persists for an extended period of time, resulting in friction, overheating, and causes of compressor burnout.

Unacceptable Noise

A problem with your air compression system frequently manifests itself audibly. Air leaks are obviously audible and need to be repaired right away. Strange bearing noises may also point to an alignment issue or another maintenance issue. An additional version on this issue is excessive vibration.

Transmission of Oil

Too much oil can enter the compressed air flow when the air/oil separator is saturated, harming the entire compressed air system. Oil carry-over rates for oil-lubricated air compressors typically range from 3 to 5 ppm.

Pressure Decrease

Your compressed air system will be significantly less effective if there are air leaks in the distribution system. Furthermore, it will force your compressor to work harder in order to produce a smaller flow of compressed air.

Air Compressor Problems And Solutions

The list of these avertable reasons is provided below to help you avoid future headaches.

Maintenance in Advance

Your air compressor will prematurely fail due to a maelstrom of problems caused by improper preventative maintenance. The internals of your air compressor can be harmed by using the incorrect parts and filters. By using the incorrect oil, you could cause varnish to form inside your air compressor, which would require extensive repair work or What Causes air compressor to fail. Missing crucial checks can result in highly expensive repairs or even total failure.

Changes of Oil

Your machine will prematurely fail due to overheating, varnishing, premature bearing failure, high TAN levels, and corrosion if you don’t undertake routine oil changes and oil sampling.

Contaminated Air

Any contaminants in the surrounding air can mix with the oil and cause additional chemical and physical changes to the oil, which, if left unattended, can significantly shorten the lifespan of your compressor.

Adapter Alignment

A misaligned connection between your electric or fuel-powered motor and your compressing unit will cause early bearing wear, vibration problems, and other problems throughout the machine.

Suitable Installation

Your air compressor’s location is essential to the health of your overall compressed air system. The installation of your air compressor is where it all begins. A bad installation position could cause contaminated ambient air to enter the air compressor, setting off a ticking time bomb that eventually results in the air compressor failing.

Electricity Problems

In order to be as efficient as possible, electrical equipment is constructed with very small tolerances. All electrical equipment includes variations that are specified, and while they may not be the most productive, they will still function. Issues start to appear when your air compressor is used within the variance range. Electric motors operating at low or high voltages have the potential to fail air compressors. Electricity issue at home also comes in the factors of What Causes air compressor to fail.

How to Avoid Air Compressor Failure

You can prevent the majority of cases of air compressor failure by paying attention to the crucial maintenance areas listed below.

Air Purifiers

Millions of dust particles, water vapour, and contaminants are likewise squeezed into a smaller volume of “normal” air. At each step of the procedure, we filter contaminants out of the compressed air that enters your system using air filters. They are consequently among the most crucial parts of your compressed air system.

Cartridges for Inlet Filters

Weekly vent cleaning and inlet filter replacement as advised by your compressor’s manufacturer.

Linear Air Filters

To find out how frequently you should change your air line filters, you should refer to your manufacturer’s instructions. Don’t stop there though. You should keep a close eye on your filter.

Sewage Traps

Regularly check and clean drains to get rid of scale, rust, debris and other solids that could clog a drain and collect liquid from moisture separators.

Engine Bearings

For advice on lubricating your compressor’s motor bearings, contact the manufacturer of those bearings. They may advise you on how much grease to use, how frequently, and what kind is needed.

Compressor Oil

Before starting your compressor each day, check the oil level. As oil droplets are taken up by the air, escape, or are eliminated by the air filters and drainage system, the amount of oil in your compressor reduces.

Oil Filters

Oil filters should be changed at least every 2,000 hours (or more frequently if your manufacturer so advises). Oil filters remove calcium, metal filings, and other impurities, extending the usable life of your compressor.

Conclusion

What Causes air compressor to fail? You must keep your aye on the causes. The performance and lifespan of your air compressor, which is the core of your facility’s compressed air system and its “fourth utility,” are improved and extended by preventing and predicting problems before they arise. Hope this article will definitely help you in thoroughly taking insights of what causes air compressors to fail.

Read More Articles

| How Long Should a Sump Pump Run |

| Where Does Sump Pump Water Go |

| How Often Replace Sump Pump |